Understanding Different Forklift Types & Their Uses

At Coapchain Group, we believe in equipping our clients not just with machinery, but with knowledge. Choosing the right forklift type can improve safety, reduce costs, and optimise performance. Below is an illustrated guide to common forklift types, their strengths, and ideal use cases.

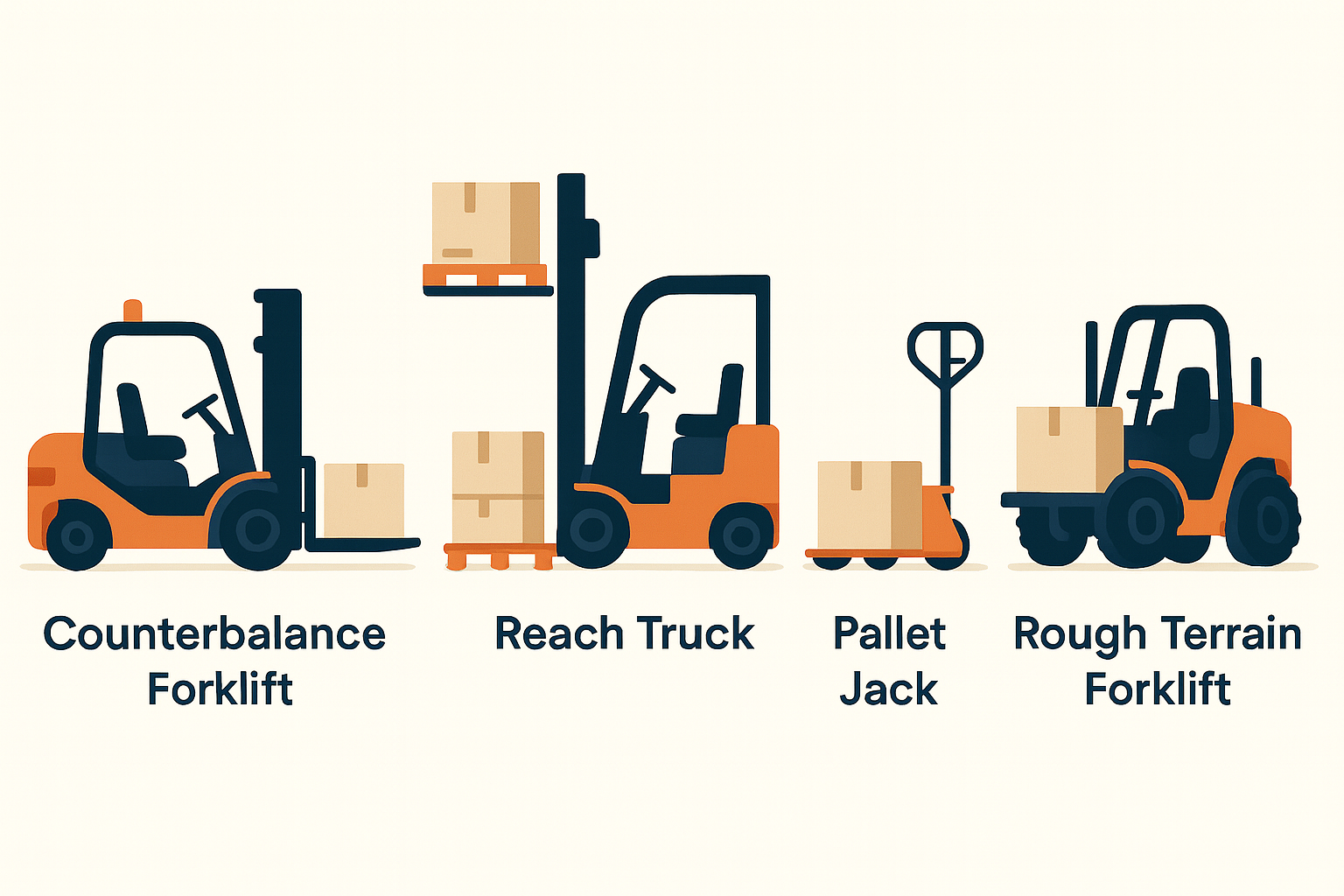

1. Counterbalance / Warehouse Forklift

What it is: The classic “front fork + rear counterweight” design.

Strengths: Simple, versatile, great indoors or outdoors on flat surfaces.

Best for: Pallet handling, general warehouse operations.

2. Telehandler / Telescopic Handler

What it is: A forklift-crane hybrid with extendable boom.

Strengths: Reach & lift over obstacles, use multiple attachments.

Best for: Construction, agriculture, and loading/unloading at height.

3. Rough Terrain Forklift

What it is: Heavy-duty tyres, robust frame, built for uneven ground.

Strengths: Stability on outdoor terrain, strong lifting capabilities.

Best for: Construction sites, farms, and outdoor storage yards.

4. Side Loader Forklift

What it is: Forks mounted perpendicularly; loads come from the side.

Strengths: Ideal for handling long, bulky items (pipes, beams).

Best for: Steel manufacturing, lumber yards, long goods storage.

5. Pallet Jack & Walkie Stacker

What they are: Entry-level handling machines—electric or manual.

Strengths: Compact, manoeuvrable, lightweight operation.

Best suited for: Tight warehouse aisles and internal pallet movement.

6. Order Picker

What it is: The Operator lifts the goods to pick from the shelves.

Strengths: Direct access to inventory, especially in high-rack settings.

Best for: E-commerce, high-density storage, retail warehouses.

7. Reach Truck

What it is: Narrow-aisle forklift with extended mast capabilities.

Strengths: Operates in cramped aisles and high lifting.

Best for: High-rack warehouses, tight storage environments.

8. Heavy-Duty / High-Capacity Forklifts

What it is: Built for hefty loads (e.g. 20+ tons).

Strengths: Strong frames, powerful hydraulics, durable design.

Best for: Ports, steel yards, heavy manufacturing facilities.

9. Walkie Stacker / Rider Pallet Truck

What it is: Walk-behind or ride-on pallet trucks with lift ability.

Strengths: Cost-effective for lighter loads, small footprint.

Best for: Small warehouses or stockrooms.

10. Tow Tractor / Tug

What it is: Pulls loads rather than lifting them; sometimes under forklift classes.

Strengths: Efficient for tugging carts, baggage, or material trains.

Best suited for: airports, factories, and assembly lines.

Choosing the Right Forklift for You

-

Load weight & size — Always pick a forklift with a rating above your max load.

-

Terrain & surface — Smooth indoor floors favour electric/cushion tyres; rugged outdoor ground demands pneumatic or rough-terrain types.

-

Height & reach needs — High racks require tall masts or telehandlers.

-

Work environment — Indoor settings often require zero-emission electric; outdoor settings may need combustion or hybrid options.

-

Space constraints — Narrow aisles need reach trucks or side loaders.

-

Maintenance & serviceability — Use genuine parts and partner with providers who understand your operation.

Why Coapchain Group Stands Out

With over 17 years of serving Europe and more than 52 countries globally, Coapchain offers not just machinery, but a full spectrum of support: rentals, maintenance, training, and parts. Whether you need a compact warehouse lift, a powerful telehandler, or a rough-terrain beast, we support you at every stage—from selection to upkeep.